3D printing is not only becoming increasingly attractive to individuals, but it also offers many new opportunities for businesses.

But what are the commercial uses for a 3D printer and how much does a professional device cost? What do you need to look out for when you buy it and what else do you need besides the printer itself?

What exactly is a 3D printer and how exactly does it work?

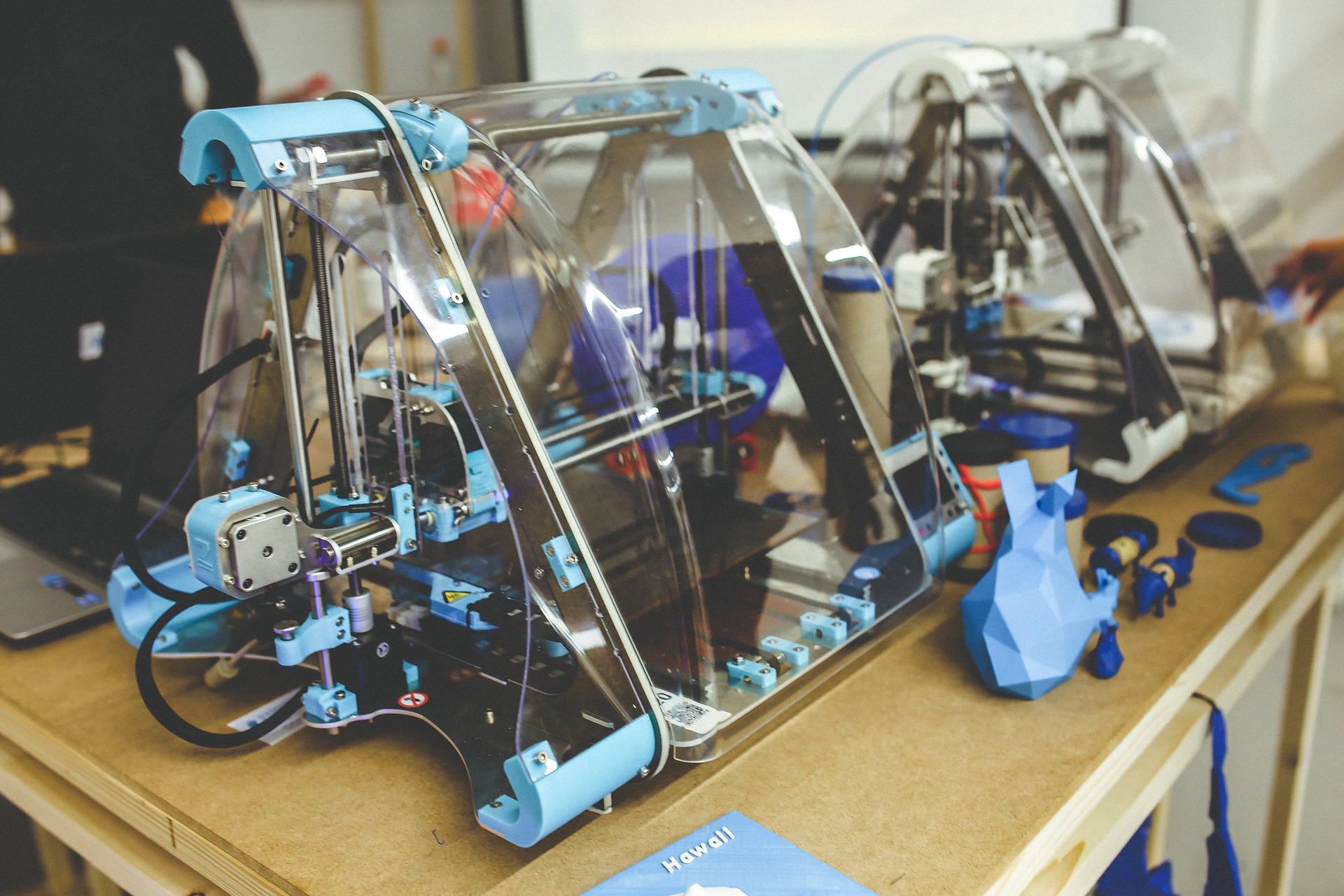

A 3D printer is a device that creates or prints three-dimensional objects.

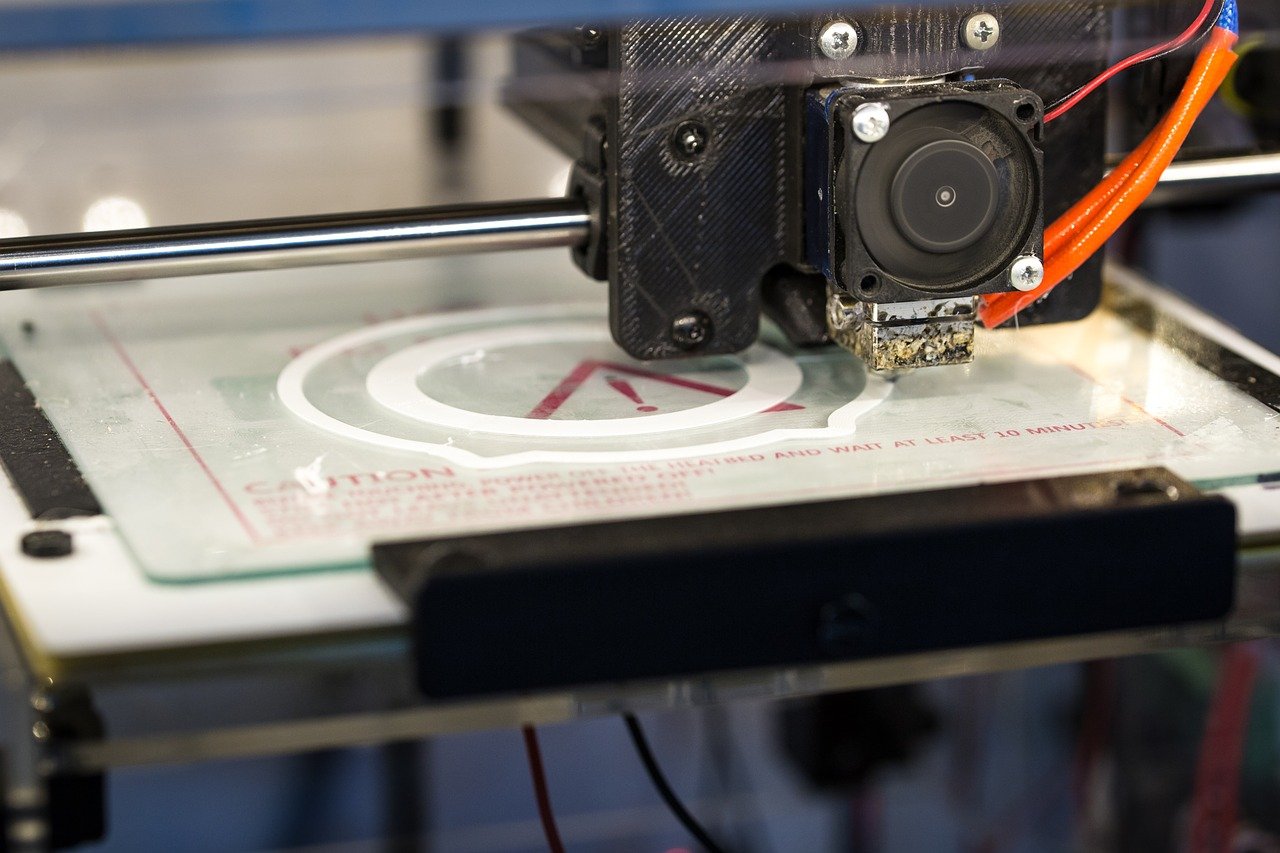

In 3D printing, also known as additive manufacturing, the material is applied layer by layer to ultimately create the three-dimensional object.

The layer-by-layer construction of the liquid or solid materials is entirely computer-controlled. The materials used for additive manufacturing are typically resins, plastics, metals and ceramics, depending on requirements.

Why is this technology becoming more and more interesting for companies and when is it worthwhile to purchase it and when can an external service provider be an alternative?

As the price of 3D printers drops, more and more companies are considering purchasing their own equipment.

The key advantage of this new technology is that young startups can develop their own products or prototypes to market much faster.

As a result, the corresponding articles are then sold much faster.

But also already existing companies, which have been using other manufacturing processes so far, have long since realized that significant time and cost savings are possible due to the reproducible quality.

With 3D printing, small batches can be produced and ultimately sold to the end user at a profit.

What are the commercial uses for 3D printers and what are the most popular industries?

3D printing is already widely used in the medical industry, for example, to produce prosthetics or other unique pieces at low cost.

The aerospace industry is also already making full use of additive manufacturing, which can be used to produce lightweight aircraft parts that can significantly reduce fuel consumption.

For example, the armrests of airplanes are already increasingly coming from the 3D printer. Fashion labels and sporting goods manufacturers also see 3D printing as a great opportunity to create unique, individual pieces.

For example, the first attempts are already being made to produce customized running shoes, which refers to individual elements such as soles and midsoles.

However, the new technology will revolutionize many other areas in the future, and it is expected that the variety of products in the retail sector will increase considerably.

What does it take to use a 3D printer?

Buying a 3D printer isn’t the end of the story, because you need to do a lot of setup, preparation and post-processing.

One of the most important things is a clean STL file of the object to be printed, so of course you need a computer.

In addition, there are various materials available in stores for the 3D printer, which are also needed to create a three-dimensional print model.

When in doubt, a professional 3D printing service like ours can also help you choose the right accessories.

How expensive are professional 3D printers today, and what should you look for when buying a 3D printer?

While 3D printers were almost unaffordable until a few years ago, they are now available at relatively low prices. It’s important to differentiate between whether the device is for personal or commercial use.

While the price range for a home 3D printer is 300 to 5,000 Euros, a professional model can be worth a high six-figure sum.

It is important to consider the area of application when purchasing. It’s important to choose the right 3D printing process based on the intended use of the 3D printer.

To get started, you might want to work with experienced service providers and see which one works best for your industry.

This will save you the initial investment and knowledge of 3D printing, so you can learn it step-by-step without time pressure.

Last but not least, it is important that the printer is optimally adapted to the operational requirements, as this is the only way to achieve significant time and cost savings.

Conclusion:

3D printers are becoming increasingly popular with businesses because of their versatility. The benefits of additive manufacturing are astounding for the commercial market, and more and more small businesses and start-up companies are considering 3D printing. More here: https://www.pressebox.de/pressemitteilung/hans-kemeny-deutsche-marketing-consulting/Marine-setzt-auf-3D-Druck-von-SPEE3D/boxid/1028292